The Power of Celonis Process Mining in Order Management

Process mining is a powerful tool wherever you apply it. Here’s a look at how using it in Order Management can drive results for you and your team.

Achieving operational excellence in Order Management isn’t easy. With customer-facing operations and continuous collaboration required with other departments, there are many moving parts to keep track of, and countless opportunities for inefficiency to creep in undetected.

That’s where process mining comes in. With the ability to shine a light on hard to detect sources of process inefficiency and performance dips, it’s quickly becoming a must-have capability for virtually every function — and Order Management is no exception.

What is process mining?

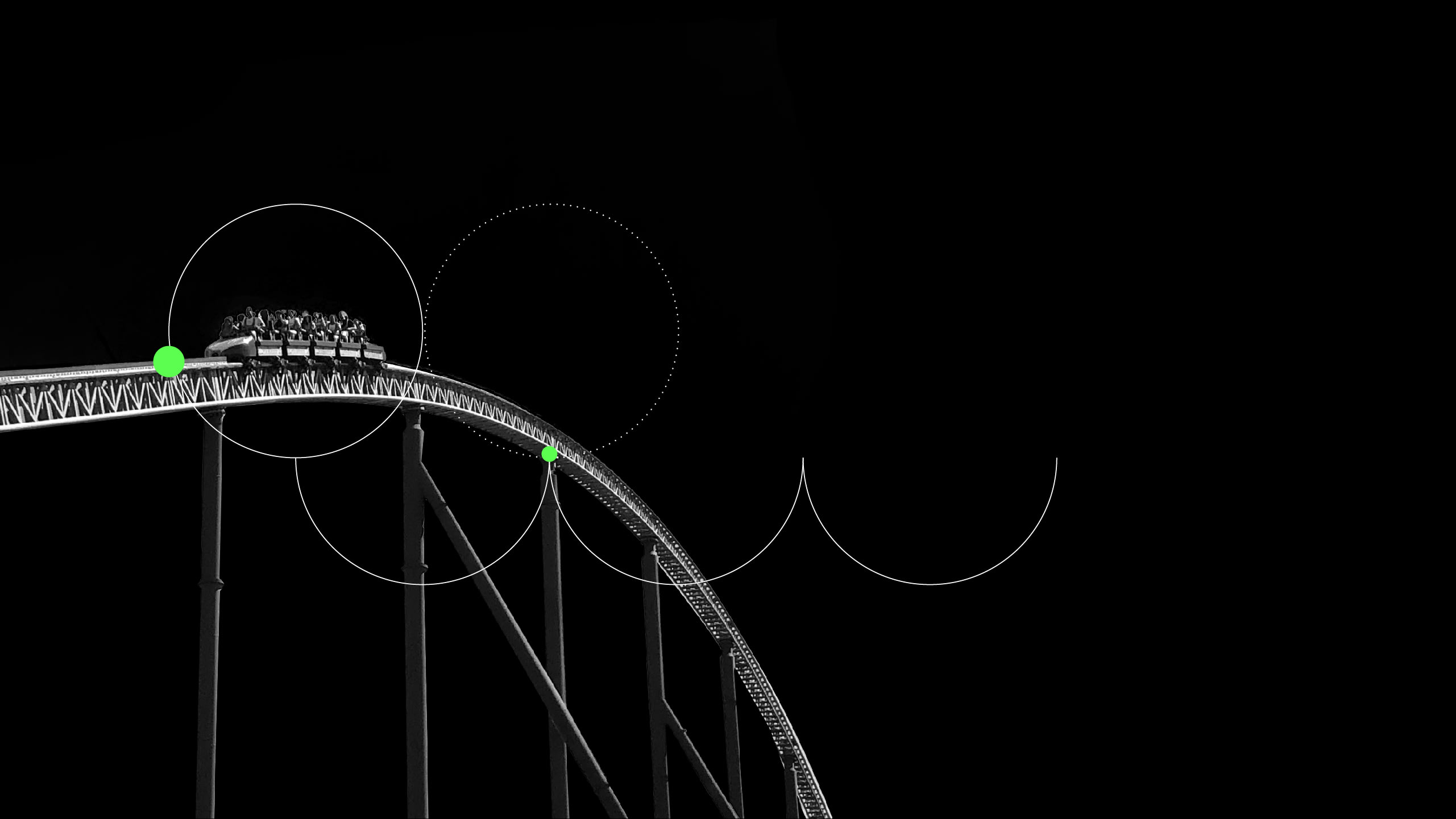

Process mining enables users to visualize and monitor business processes, using live data from underlying transactional systems to show process steps as they are, rather than how stakeholders or even process owners believe they run.

So how does process mining work? By pulling data and event logs from live systems and platforms, you can get comprehensive, real-time visibility into your processes and see where they’re underperforming. It’s like a process X-ray, and it means the insights generated are not only highly reliable, but also clearly actionable. Process mining insights don’t just tell you that you have a problem — they help you dig down and address its root cause.

In short, process mining in Order Management gives you both the confidence and visibility needed to act on insights immediately by taking targeted action to improve process performance.

Why would you want to use process mining in Order Management?

Process mining has powerful applications in virtually all functions, but some of its strongest use cases lie within Order Management.

Order Management sits in a unique position within a business. It’s a customer-facing and critical part of the Order-to-Cash process, deeply entwining it with functions like Accounts Receivable. As a result, process inefficiency in Order Management can quickly spill outwards in multiple directions.

Examples such as credit blocks or inaccurate address data can lead to delivery delays, returns, reduced customer satisfaction, and delayed payment. That’s why process excellence in Order Management is essential.

Fortunately, the inverse is also true. Once you use process mining to uncover the issues impacting Order Management processes and take the right action to resolve them, the benefits cascade outwards in a similar fashion. Gains and optimizations are felt further down the Order-to-Cash chain, improving the A/R team’s KPIs too, and ensuring that customers stay happy, satisfied and loyal.

What is Accounts Receivable? The process, KPIs and metrics that matter

How does process mining work in Order Management?

Order Management process mining can deliver a similar depth of understanding and visibility as an explorative process mapping consulting exercise. But rather than spending months in workshops, all you need to do is take the first steps to implement process mining within your organization in order to get a comprehensive view of what’s going on within the business — with the added benefit of being both objective and available in real-time.

Which is great for things like:

Identifying opportunities for automation across Order Management processesand surfacing error-prone process areas.

Minimizing delivery blocks that can lead to late deliveries and reduce customer satisfaction.

Preventing incomplete deliveries and improving collaboration between Procurement, Order Management, and Fulfillment.

Now let’s dig into some use cases in a bit more detail.

Use cases for process mining in Order Management

Process mining applied across Order Management processes grants visibility to the blockers and issues impacting customer satisfaction and the organizations’ bottom line. Here are three of the most common use cases Order Management teams are using process mining for:

Use case #1: Minimizing credit holds

When sales orders are placed on hold due to credit status, even your most consistent, longest-standing customers can face serious delays in the delivery of their orders. That’s not just an unplanned blocker in your processes, it can lead to major dissatisfaction and cause damage to customer relationships that you’ve spent years building.

Process mining will help Order Management teams discover the root causes of credit holds and slow credit approval processes, then enable them to take the right action. Often a preventative action involves applying automation to ensure that as credit lines approach their expiry, they’re renewed without impacting delivery or order processing times.

Use Case #2: Preventing late deliveries

On-time delivery is the central goal for the Order Management department. Order entry errors, delivery blocks, and silos between the procurement and order management organizations are all common causes of late delivery. Applying process mining can help you tackle all of them.

Process mining in Order Management can help uncover the diverse causes of orders that are not going to meet promised commitments, ship dates, and delivery dates. Having a real-time view into your business processes will let your team see errors or holds, enabling them to get ahead of issues, so your orders are delivered on time.

Use case #3: Preventing order rejections

Nobody wants to reject orders from loyal and valuable customers. But when supply and demand don’t line up, it’s often unavoidable.

With process mining, you can spot frequent sources of rejections, identify problem materials or goods, and adjust your procurement and supply chain strategy in line with real demand.

You can even see which customers are frequently having their orders rejected and take action to prioritize when supply runs short so unforeseen spikes don’t threaten your most valuable accounts.

What benefits can process mining bring to Order Management?

Beyond those use cases, process mining can help the Order Management function achieve three of its biggest and most important goals:

Improve customer experience: In Order Management, process delays directly lead to customer dissatisfaction — whether that’s thanks to manual order changes, price changes, or delays in delivery.Process mining helps you identify the root causes of all three so you can keep processes running smoothly and keep your customers happy every step of the way.

Increase productivity: Across Order Management, there are numerous opportunities to automate processes — improving productivity and reducing human error. Process mining can show you where those opportunities are by clearly highlighting the areas most prone to errors and delays, and showing you parts of your processes that could most easily be automated.

Boost on-time delivery rate: Process mining enables you to see the percentage of deliveries that are made on time and understand why the others were not. It gives you a simple way of surfacing the underlying drivers of late deliveries, so you can resolve them quickly, prevent delays, and achieve higher, more consistent on-time delivery rates.

How deep does process mining go?

Process mining grants granular visibility of processes and operations, enabling you to surface issues and blockers at an order or customer level. For any blocker, you can immediately see the orders related to it, how that blocker has impacted performance against KPIs, and which parties were involved in its origination.

But when it comes to fully understanding process performance that’s just one part of the puzzle. To get the complete picture of your processes, you also need the visibility of what happens between the steps of your transactional systems. That’s where task mining comes in.

Task mining grants desktop-level process visibility, helping you track individual click paths when performing common tasks like updating contracts or engaging with a customer.

When paired with process mining, it can help you track process blockers and issues right down to the individual click that caused them, helping you to understand the problem and action it with pinpoint accuracy.

Task mining capabilities are essential if you want to understand processes at depth.

What challenges might you face when using process mining in Order Management?

Getting started with process mining in Order Management is a relatively simple process. Once you’ve selected a tool or platform from a partner like Celonis, all you need to do is choose the right data connectors, pull in data from relevant live systems, and start generating insights.

Using process mining in the Order Management function can present significant cultural and process changes in itself. To get the most from process mining capabilities, teams must learn to trust them and appreciate the insights they generate as a true reflection of live processes.

Lingering attitudes towards BI tools that are often fuelled by imperfect or unreliable data can hold process mining back. For teams to make the most of what process mining can deliver, they’ll have to be empowered with an understanding of how the technology works - so that they have confidence around questions like “Where has this data come from?” “Can I trust these insights?” “And is this truly reflective of our operations today?”

See the power of Order Management process mining for yourself

Celonis process mining represents a huge step forward in business and operational intelligence. By giving organizations a reliable, timely view of how today’s processes realistically look, it enables them to make better-informed decisions and precisely targeted optimizations right across their operations.

Celonis has been helping businesses discover and harness that power for years. To find out exactly how much money you are leaving on the table in Order Management — and how much you could stand to gain by optimizing your process with Celonis, try the value calculator now.