The Insider's Guide to Supply-Chain Optimization

Find hidden opportunities in your supply chain and make it work as one.

01 Supply chains aren’t under control

Supply chains are under enormous pressure from unpredictable customer buying behavior, ongoing material shortages, ESG goals, evolving tech, and macroeconomic turbulence. The Global Supply Chain Pressure Index (GSCPI) may have dropped significantly at the start of 2023, but now, the pressure is rising again.

Lora Cecere

Founder of Supply Chain Insights

” The supply chain team is attempting to drive uphill, but visibility is low, and uncertainty is high.”

$800 billion

To thrive in this uncertainty, businesses must take control of their supply chains and deliver value. But despite valiant efforts, supply chain problems aren’t being solved. In fact, supply chain issues are expected to cost CPG brands around about $800 billion in top-line growth over the next five years.

The supply chain trade-off

Capturing value is a challenge for supply chain leaders because there’s a constant trade-off between achieving service levels, optimizing working capital, and containing costs.

Click below to see how improvements in any one of these areas can have a negative impact on the others.

For your supply chain to be under control and operating at peak performance, these three elements need to work in harmony. But traditional methods for transforming supply chains are too piecemeal to achieve that balance.

The great disconnect

Balancing service levels, costs, and working capital is hard when each part of the supply chain operates and innovates within its own lane.

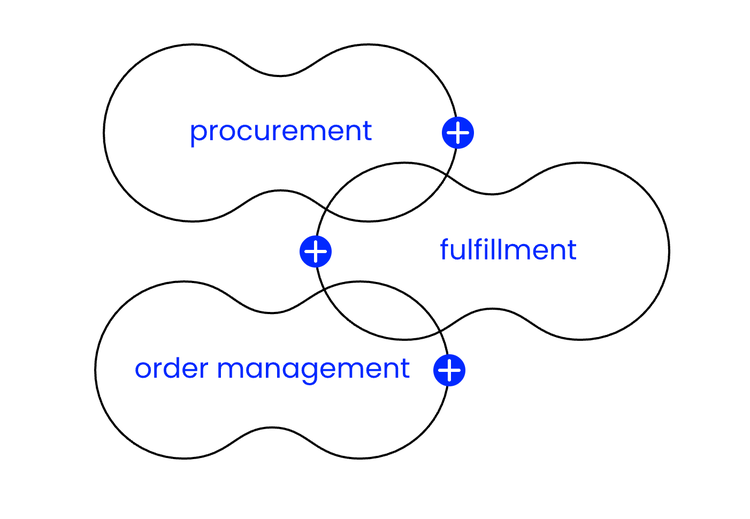

Individual teams such as procurement, production, and distribution can invest in new technologies, redesign networks, and reorganize responsibilities. But when they stay within departmental silos, changes made in one department can have unintended upstream or downstream consequences for other teams.

There’s an obvious answer

There is a simple answer, but everyone’s missing it because they’re looking in the wrong direction. Traditional attempts at maximizing efficiency fail to look at the very thing supply chains are made of:

Put simply, supply chain problems are process problems, so a process-first approach is needed to optimize your supply chain.

Put simply, supply chain problems are process problems, so a process-first approach is needed to optimize your supply chain.

02 The supply chain is a mega process

Supply chains are effectively one mega-process made up of lots of connected micro-processes. So a process-first approach is needed to maximize efficiency and improve supply chain performance.

But all these micro-processes are happening in different systems, handled by different people, in different teams, with very little interdepartmental visibility. Systems don’t play well together and departments don’t speak the same language. There’s a missing shared understanding of how the supply chain runs, end-to-end.

A process-first approach

Instead of finger pointing, your business can get its supply chain working as one by fixing the processes that make it run. With Celonis Process Intelligence as the connective tissue of your enterprise, you can use process mining identify even small opportunities in the processes contained within each individual link — opportunities that can have a huge impact on the rest of the supply chain.

And, with process mining, you can also zoom out and look holistically across processes, taking an end-to-end approach so you can see how a small change in one area will impact everything else.

Which process to start with?

The great thing about a process-first approach to supply chain optimization is you can start with any entry point.

Because you have an end-to-end view, you can use process mining to help pinpoint opportunities for improvement in any process in your supply chain. You can delve into different processes and identify opportunities at any single point, see the upstream and downstream impact, and make incremental gains across the whole supply chain.

Explore the supply chain below to discover the processes you can optimize, the metrics you can improve, and the results you can expect at every stage.

Which process to start with?

Alternatively, you might choose to start by focusing on a particular KPI that you already know your business needs to improve.

Check out our on-demand webinar Transforming the Top 5 Supply Chain Metrics with Process Mining to discover how you can improve:

- Perfect order index

- Cash-to-cash time

- Supply chain cycle time

- Fill rate

- Inventory turnover

03 Perfecting Procurement

Procurement covers areas of the supply chain such as sourcing, where there are a variety of opportunities hidden in processes.

One key area to explore could be supplier management, where process mining is used to discover how suppliers are performing. You can find out where on-time delivery or reliability rates are low, or where prices are higher than expected, and why this is happening.

Fixing a problem and creating value might be as simple as correcting payment terms to prevent late supplier deliveries, updating to more realistic lead times, or linking contracts to purchase orders so materials aren’t at risk of price variability.

When you know where problems are arising and why, it’s easier to find solutions

Tech Data

Customer story

Tech Data merged with SYNNEX to become TD SYNNEX, the largest IT distributor in the world. It uses Celonis to increase visibility into areas such as procurement, and to provide a foundation of operational excellence.

In one analysis, Tech Data discovered that, among the millions of transactions it processes per year, around 30% of the purchase orders were subject to price changes or cancellation. The team identified the problem and reduced the price change ratio by 27% in six months, which contributed to an overall 57% reduction in procure-to-pay total cycle time in just one year.

04 Fine-tuning Fulfillment

Fulfillment covers multiple parts of the supply chain, including production, warehouse, inventory, and logistics. There are almost limitless processes that can be streamlined and improved.

Let’s take Inventory Management as an example. Production and supplier lead times have always been a blind spot when calculating safety stock levels or order points. Usually material planners rely on what the supplier tells them, or their own knowledge, but this results in both excess inventory and stockouts.

With process mining to help, you can identify the actual lead time and use it to calculate the right safety stock and reorder points to meet service levels without risking excess inventory.

Manroland Goss

For manufacturer Manroland Goss, calculating lead times and safety stock levels used to be a manual process involving SAP exports, quarterly reviews, and lots of Excel spreadsheets. This reliance on manual analysis and lead time information from suppliers resulted in outdated safety stock calculations — which in turn led to both stockouts and excess inventory.

With the help of the Celonis Planning Parameter Optimization App, the company was able to tailor the lead time formula to focus on demand for specific material types, touching 30% of the business. Material planners can now use the app to review all safety stock levels across over 10,000 materials and €17MM in Procurement spend.

From reviewing materials every three months, the team now has a view that allows them to review safety stock levels daily. And with the ability to automatically update safety stock levels and lead times across all SKUs, Manroland Goss realized value within one month of implementation

Thomas Stoll

Head of Supply Chain, Procurement and Logistics Manroland Goss

”The app is easily customizable, which made our users trust the recommendations and leverage the write-back functionality that keeps our SKUs up to date and enables us to overcome today’s volatility.”

05 Optimizing Order Management

Order Management covers the order and fulfillment stages of the supply chain — the steps between the customer placing an order and money being received.

Opportunities within Order Management processes could include identifying issues that are preventing on-time delivery — such as unnecessary order limits and credit checks, or unforeseen inventory issues — and then taking action to resolve these.

They might also include understanding the root causes of order cancellations, rejections, changes or returns. Actions as simple as identifying and eliminating product or shipment entry errors may resolve some of these issues and reduce the need for manual intervention.

Hexion

Customer story

Specialty chemical manufacturer Hexion has a large, complex supply chain, where understanding the ripple effect of process steps upstream or downstream is challenging. With Celonis, Hexion found an incredible 10,000 variants in its Order-to-Cash process, and can see how this high variability impacts adjacent processes in production planning or procurement.

Hexion discovered a high number of route changes was significantly increasing delivery times, and made simple changes in the master data to reduce these changes by 45%. It also set up automated blocked order notifications, reducing the time from credit hold release to shipment from 11 to five days and significantly improving customer experiences.

Javier Invernizzi

VP of Global Supply Chain,

Hexion

”With Celonis, we’ve been able to see where our order-to-cash opportunities really are. We’ve seen which manual touches we can eliminate or automate, and we’ve started to re-evaluate decisions we didn’t even know we were making. The same goes for our procure-to-pay and production planning processes, all of which are connected.”

06 Sustainability in the supply chain

Sustainability is an increasingly important component of any organization’s supply chain strategy — and, in some regions, efficient, environmentally conscious business practices are increasingly required by law. Many businesses are already including sustainability in the service levels, cost, cash equation as something that must be accounted for when balancing priorities.

Taking opportunities to increase efficiency in the supply chain can tangibly improve sustainability metrics using the same process mining technologies used for supply chain optimization. A process-led approach helps organizations improve KPIs such as shipping emissions and sustainable spend.

Opportunities to improve sustainability

Explore the supply chain below to reveal some of the opportunities to improve sustainability metrics, hidden in your processes.