Sustainability at Celonis

We are here to unlock the potential of the world’s processes, to make them work for the planet rather than against it. One of our core values is ‘Earth is our future’, and one of our key value propositions is delivering green value for our customers.

Because we wanted to make sure any sustainability initiatives we launched were truly impactful for our stakeholders — both internal and external — we started with a comprehensive materiality assessment and continuously report on our progress and commitments. Read more about it in our Sustainability Report.

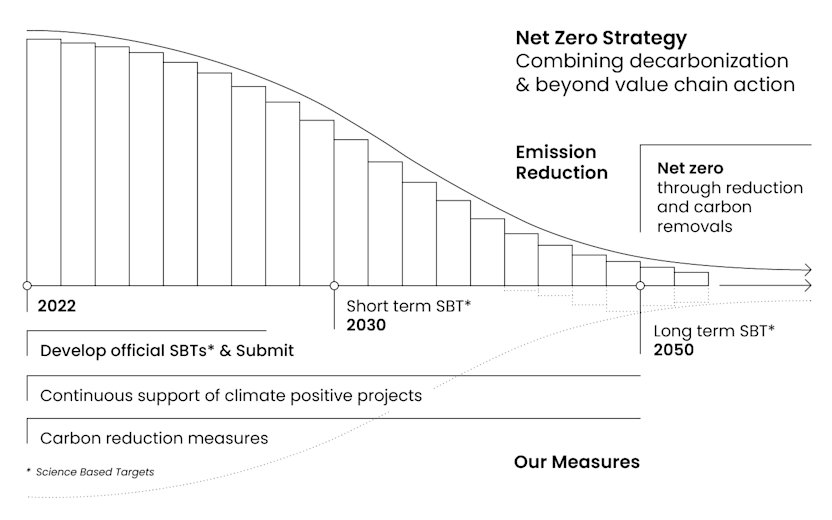

Our Net Zero Climate Program

To limit global warming to no more than 1.5°C – as called for in the Paris Agreement – global emissions need to be reduced by 45% by 2030 and a state of net zero needs to be reached by 2050.

In order to play our part in meeting that target, we have set up our Climate Action Plan, which includes reduction targets, clear reduction measures, and investments in high-quality climate projects beyond our own value chain.

Celonis has committed to set near- and long-term science-based targets in line with the Science Based Targets initiative (SBTi) Net-Zero Standard. This standard represents the most ambitious and globally recognized framework for climate target setting. We plan to submit our sustainable goals to the SBTi in 2023.

Alongside committing to setting SBTs, Celonis has also joined several coalitions: Business Ambition for 1.5°, Race to Zero, and the We Mean Business Coalition. We are excited to have those new platforms to exchange with other companies on the journey towards net zero.

Delivering green value

Today, only 1 in 2 businesses are achieving their environmental goals.

While many organizations have started to invest in reporting, they struggle to operationalize their sustainability strategy. Their operational data is spread across a complex landscape of systems, people, and processes and the methods for collecting that data are manual, and error-prone.

This is where we can help.

Our Global Impact Days

We give Celonauts time and resources to step away from daily work and devote themselves to causes meaningful to them. We call these Celonis Impact Days.

Every Celonaut can spend up to three days in the year giving back to their communities. They decide how they use their Impact time and organize projects - creating impact for Celonis’ sustainability program, customers, society or the planet. Are you interested in collaborating with us on our Celonis Impact Days? We already worked together with 100+ charities, associations, and non-governmental organizations and supported them with hands-on activities or professional expertise. Your organization would like to set up an Impact Day project together with us that fits into one work day? Send us an email and our Sustainability Team will get in touch with you shortly!

Leading by example

Celonis4Sustainability is our employee-led community providing the opportunity for contribution to Celonauts that feel passionate about sustainability. In bi-monthly gatherings facilitated by a set group of employees, Celonauts drive action on pressing tasks. We welcome every Celonaut to join the community to exchange, discuss and learn together with others.

Learning about what matters

Sustainability is a complex challenge, and we need to accelerate our common understanding to reach our ambitious goals. For you - our employees, customers, partners, students, and process mining enthusiasts, we created meaningful sustainability training courses on our Academy - for free and everyone:

Sustainability Base Camp

Free 2-hour training about the fundamental concepts of sustainability.

Sustainability Business Bootcamp

free 1-hour training on sustainability use cases with the Celonis EMS.

Celonis Aspire

Looking to the future, we see education as the key to unleashing everyone’s potential. We believe equal education starts with equal access.

Read more about what we do

Connect with a Celonis sustainability expert

Our dedicated sustainability team would love to hear your feedback!